Aftermarket Excavator Parts: Why They Are a Fantastic Option

Vital Tips for Choosing Aftermarket Excavator Parts for Building Projects

When it pertains to construction jobs, the option of aftermarket excavator parts plays a critical duty in ensuring the smooth operation and long life of hefty machinery. Making educated choices pertaining to the components that keep these powerful machines running efficiently can dramatically impact the project's timeline and budget. From compatibility and quality control to pricing considerations and vendor credibility, there are necessary elements to think about when selecting aftermarket excavator components. Each choice made in this procedure can either drive a project towards success or potentially result in expensive obstacles. Understanding these key ideas can make all the distinction in the efficiency and reliability of building and construction tools, inevitably affecting the task's overall end result.

Value of Compatibility

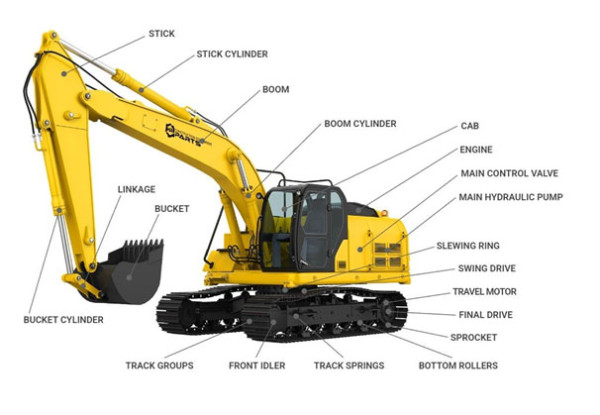

Making certain compatibility in between aftermarket excavator parts and the particular make and model of the maker is critical for ideal performance and longevity. Making use of components that are not made for a certain excavator can lead to inefficiencies, breakdowns, and also major damage to the tools. Suppliers designer excavators with particular specs and resistances, and utilizing aftermarket components that do not meet these needs can compromise the equipment's functionality.

To prevent these problems, it is important to deal with reliable suppliers that supply aftermarket components especially made for the make and version of the excavator concerned (aftermarket excavator parts). Prioritizing compatibility will aid optimize the excavator's efficiency, enhance its lifespan, and inevitably save money and time on replacements and fixings

Quality Control

Compatibility between aftermarket excavator components and the specific make and version of the equipment is crucial for ideal efficiency and longevity, emphasizing the relevance of strenuous top quality assurance procedures. Quality control in aftermarket excavator components entails stringent testing processes to make sure that the parts fulfill or go beyond sector standards. This includes worldly quality checks, dimensional precision assessments, and performance screening under various operational problems.

By applying robust high quality guarantee protocols, producers can assure the reliability and toughness of their aftermarket excavator components. Consumers benefit from this guarantee as it decreases the threat of early component failing, pricey repair services, and task hold-ups. Additionally, adherence to quality requirements improves the general security of building and construction sites by reducing the likelihood of equipment malfunctions.

Buying aftermarket excavator components that have actually gone through thorough high quality guarantee treatments supplies building business with confidence in the reliability of their tools. It additionally mirrors a dedication to providing high-grade outcomes efficiently and effectively on project websites.

Rates Factors To Consider

With cost-effectiveness being a critical aspect in procurement decisions, reviewing the rates of aftermarket excavator components is crucial for making the most of value in equipment upkeep and repair. When considering valuing for aftermarket excavator components, it is essential to strike an equilibrium in between price and top quality. It is recommended to conduct comprehensive research on the prices of numerous aftermarket components, comparing factors such as guarantee, resilience, and distributor online reputation.

Warranty and Return Plans

In addition, a clear and fair return plan is crucial in case the acquired parts are not ideal or encounter problems. aftermarket excavator parts. Consumers must recognize the return procedure, including any restocking charges or return delivery prices they might sustain. A convenient return policy indicates that the supplier is positive in their products and values client experience

Provider Track Record

Having a strong credibility in the sector is important for aftermarket excavator components vendors to build depend on with consumers and establish credibility in the marketplace. A provider's reputation is a representation of their integrity, product high quality, client click over here service, and overall performance. When selecting aftermarket excavator components, it is essential to think about the online reputation of the provider to make certain that you are obtaining top quality products and exceptional assistance.

One method to assess a distributor's reputation is by investigating customer testimonials and testimonies. Comments from previous customers can supply important understandings into the provider's performance history and the high quality of their items. Additionally, you can also check industry online forums, web sites, and social media sites systems to see what others are saying about the vendor.

An additional facet to take into consideration is the distributor's experience and long life in the market. Developed vendors with years of experience are more most likely to have a strong online reputation contrasted to newer participants. By picking a reliable supplier for your aftermarket excavator components, you can boost the success of your building jobs and make sure the durability of your equipment.

Conclusion

To conclude, when selecting aftermarket excavator components for building tasks, it is critical to focus on compatibility, quality control, prices considerations, service warranty and return plans, along with distributor online reputation. Making certain that the components are compatible with the details excavator design, are of top quality, reasonably priced, backed by a service warranty, and sourced from reliable suppliers will certainly add to the success and effectiveness of the construction task.

From compatibility and quality guarantee to pricing considerations and provider reputation, there are necessary elements to take into consideration when selecting aftermarket excavator components.Compatibility in between aftermarket excavator components and the specific make and design of the equipment is critical for optimum efficiency and durability, underscoring the value of strenuous quality guarantee measures. Quality assurance in aftermarket excavator components entails rigid screening processes to make sure that the parts go beyond or meet sector requirements. aftermarket excavator parts. When selecting aftermarket excavator parts, it is essential to consider the reputation of the distributor to make sure that you are getting premium items and outstanding support

By picking a trusted distributor for your aftermarket excavator parts, you visit homepage can improve the success of your construction jobs and make certain the longevity of your equipment.